From ForgeStar to Fungi: How Space Manufacturing & Bio-Materials Will Shape Exploration

- Mr_Solid.Liquid.Gas

- Aug 13, 2025

- 17 min read

Updated: Aug 14, 2025

The next era of space exploration will not just be about going farther — it will be about making more while we’re there.

From returnable in-orbit foundries producing defect-free alloys to living fungal composites shielding astronauts from deadly radiation, the frontier of space manufacturing is opening entirely new possibilities for human presence beyond Earth.

Advances in microgravity manufacturing promise to deliver materials with properties unachievable on Earth, from zero-defect semiconductor wafers to high-strength alloys that can withstand the extreme conditions of space travel.

At the same time, bio-materials like mycelium offer a radically different approach to construction and protection — one that could grow habitats on Mars or weave itself into spacecraft hulls.

This five-part series explores the most promising breakthroughs and boldest concepts shaping the future of off-world industry:

Inside ForgeStar-1 — the UK’s first returnable in-orbit foundry.

Zero-Gravity Semiconductors — microgravity’s potential to cut wafer defects by 80 percent.

SpaceForge’s £22.6 M Series A — what record-breaking funding means for UK space investment.

Mycotecture — growing mycelium-based habitats for Mars and beyond.

Biological Ship Hulls — fungal composites as natural radiation shields.

Together, they reveal a vision where “Made in Space” becomes not just a slogan, but a vital part of how humanity thrives among the stars.

Inside ForgeStar-1: SpaceForge’s First Returnable In-Orbit Foundry Launches in 2025

(ForgeStar-1, SpaceForge, space manufacturing, in-orbit foundry)

ForgeStar-1 is more than just another satellite launch — it represents the beginning of a new era in space manufacturing.

Developed by SpaceForge, a UK-based company pioneering returnable orbital platforms, ForgeStar-1 is set to be the world’s first returnable in-orbit foundry.

Scheduled for launch in 2025, it will test the commercial potential of producing advanced materials in microgravity — and crucially, bringing them back to Earth intact.

Why Manufacture in Space?

Manufacturing in space is not a gimmick. In microgravity, many physical processes behave differently compared to Earth.

Liquids don’t settle due to buoyancy, convection currents are minimised, and materials can solidify more evenly.

This environment can be exploited to create superior alloys, semiconductors, and crystal structures with properties impossible to achieve in terrestrial factories.

The International Space Station (ISS) has already demonstrated these advantages in small-scale experiments.

ForgeStar-1 aims to take the next step: scaling up production and returning high-value products for use on Earth.

The ForgeStar-1 Platform

Unlike most satellites, ForgeStar-1 is designed for multiple missions.

Its spacecraft bus is fully returnable, allowing it to re-enter the atmosphere, be refurbished, and relaunched.

This reusability is key to making in-orbit manufacturing commercially viable — each launch is expensive, and the ability to reuse hardware dramatically reduces costs per mission.

Inside ForgeStar-1 is a dedicated manufacturing module, equipped to conduct experiments and production runs in metals, semiconductors, and composite materials.

These payloads can be swapped between missions, meaning SpaceForge can adapt the platform to different customers and material requirements.

Microgravity Metallurgy

One of ForgeStar-1’s first missions will involve testing microgravity metallurgy — the creation of advanced metal alloys with fewer impurities and stronger crystalline structures.

On Earth, convection during solidification can cause defects and uneven distribution of alloying elements.

In space, the absence of gravity allows for a more uniform molecular arrangement, which could result in lighter, stronger, and more heat-resistant metals.

Potential applications range from turbine blades and satellite components to advanced surgical tools.

In industries where performance margins are razor-thin, even a small improvement in material quality could be transformative.

Beyond Metals: In-Orbit Foundry Potential

While ForgeStar-1’s early work will focus on metals and semiconductors, its in-orbit foundry concept could be expanded to other sectors.

These include:

Zero-defect semiconductor wafers for quantum computing and high-frequency electronics.

Pharmaceutical crystallisation — certain drugs form purer crystals in microgravity, potentially improving bioavailability.

Fibre-optic cable production, such as ZBLAN glass, which has significantly lower signal loss when made in space.

By designing ForgeStar-1 as a flexible, reconfigurable platform, SpaceForge is positioning itself to serve multiple markets as demand evolves.

The Return Journey: Thermal Protection & Recovery

Bringing delicate, high-value materials back from orbit is a significant engineering challenge.

ForgeStar-1 incorporates a proprietary heat shield system to survive re-entry.

The capsule is engineered to minimise deceleration forces and protect its payload from thermal extremes.

Once through the atmosphere, the vehicle will deploy a parachute for a controlled landing, allowing quick recovery and transport to customers.

This closed-loop approach — from launch, to manufacturing, to return — is central to SpaceForge’s business model.

Environmental & Economic Impact

Reusability is not just about cost savings; it’s also about sustainability.

By refurbishing the same platform instead of discarding it after a single mission, ForgeStar-1 reduces space debris generation.

Additionally, producing certain high-value materials in orbit could reduce the environmental footprint of Earth-based heavy industry.

Economically, success for ForgeStar-1 could make space manufacturing a genuine market sector rather than a research curiosity.

High-performance materials produced in orbit could command prices far above launch costs, especially in sectors like aerospace, defence, and advanced computing.

The UK’s Role in the New Space Race

SpaceForge’s headquarters in Cardiff, Wales, place it in a growing cluster of UK space companies.

The UK government has identified in-orbit services as a strategic growth area, and

ForgeStar-1’s launch will be closely watched as a potential flagship for British space innovation.

With the £22.6 million Series A funding secured in 2025, SpaceForge has the financial backing to scale production and explore further iterations of its returnable platforms.

If ForgeStar-1 proves successful, a fleet of returnable foundries could be orbiting within the next decade.

Looking Ahead

ForgeStar-1 is more than just a single satellite mission; it’s a testbed for a new industrial frontier.

By combining microgravity’s unique physics with reusable spacecraft engineering, SpaceForge is laying the groundwork for an era where factories orbit Earth and deliver products with performance levels unachievable on the ground.

In the 20th century, the space race was about reaching orbit and landing on the Moon.

In the 21st century, it may be about turning that orbital vantage point into a place of production.

If ForgeStar-1 succeeds, the term “made in space” could soon be as common as “made in Britain” — with Cardiff at the heart of it.

Zero-Gravity Semiconductors:

How Microgravity Could Cut Wafer Defects by 80 Percent

(zero-gravity semiconductors, microgravity manufacturing, wafer defects)

In the world of modern electronics, the semiconductor wafer is king.

Every smartphone, satellite, quantum computer, and AI accelerator chip begins life as a thin slice of silicon or another semiconductor material.

But the smaller the transistors get, the more vulnerable wafers are to microscopic defects that can compromise performance — or render a chip completely useless.

Now, scientists and engineers are looking to an unexpected manufacturing environment to tackle this problem: microgravity.

With the launch of dedicated orbital manufacturing platforms such as ForgeStar-1, the concept of zero-gravity semiconductors is moving from research experiment to commercial reality.

Why Microgravity Changes the Game

On Earth, crystal growth in semiconductors is affected by convection, sedimentation, and buoyancy-driven flows in molten material.

As molten silicon cools and crystallises, these effects can cause irregularities in atomic structure, introduce unwanted impurities, and create lattice dislocations.

Even with advanced cleanroom controls, wafer defect rates remain a persistent cost driver in semiconductor fabrication.

In space, however, gravity-driven convection essentially disappears.

Without buoyancy forces stirring the melt, atoms arrange themselves more uniformly during crystal growth.

This leads to purer, more perfect crystal structures, potentially reducing wafer defect rates by as much as 80 percent, according to results from International Space Station (ISS) materials science experiments.

The ISS Proof-of-Concept

Over the past decade, the ISS has hosted several semiconductor and crystal growth experiments, producing compelling results:

Gallium arsenide (GaAs) wafers grown in microgravity displayed significantly fewer inclusions and better uniformity.

Zinc selenide (ZnSe) and other compound semiconductors formed larger, more perfect crystals, improving optical and electronic properties.

Even silicon carbide (SiC), known for its challenging manufacturing process, showed measurable improvements in defect density.

The limitation? The ISS is a shared research platform with limited access and no dedicated large-scale semiconductor fabrication capability. That’s where commercial players like SpaceForge step in.

ForgeStar-1 and the Orbital Fab Concept

With ForgeStar-1 — the UK’s first returnable in-orbit foundry — microgravity manufacturing could finally scale to meet commercial demand.

The satellite’s modular design allows for dedicated semiconductor production payloads.

Once wafers are grown and processed in orbit, the returnable capsule will re-enter Earth’s atmosphere, protecting its delicate cargo with a proprietary heat shield.

The ability to return high-value products intact is crucial.

Unlike in-space applications (such as using parts directly on satellites), semiconductor wafers grown in orbit must be packaged, diced, and integrated into terrestrial supply chains — and that requires them back on Earth in perfect condition.

Cutting Wafer Defects: The Technical Advantage

Reducing defect rates by up to 80 percent has massive implications for chip performance, yield, and cost:

Higher yields mean more chips per wafer, lowering production costs for advanced nodes.

Improved electrical properties — fewer dislocations reduce leakage currents and improve carrier mobility.

Enhanced reliability — fewer defects mean longer device lifespans, critical for aerospace and defence systems.

Quantum-ready materials — superconducting and optoelectronic devices benefit from ultra-pure crystalline structures.

Even if only high-end sectors such as quantum computing, military avionics, and deep-space communication adopt zero-gravity semiconductors at first, the commercial precedent could push wider industry adoption.

Beyond Silicon: Exotic Semiconductor Growth in Space

While silicon will remain the mainstream semiconductor material for years, microgravity manufacturing could unlock better production of exotic compounds:

Gallium nitride (GaN) for high-frequency power electronics.

Indium phosphide (InP) for ultra-fast optical communication.

Cadmium zinc telluride (CdZnTe) for advanced radiation detectors.

These materials often suffer from severe defect challenges on Earth, limiting their scale of production. Orbital growth environments could change that.

Economic and Strategic Impact

The semiconductor industry is a $600+ billion global market, and demand is only growing.

Countries are already investing heavily in domestic chip fabrication to reduce supply chain vulnerabilities.

If microgravity manufacturing proves cost-effective for certain high-value wafer types, it could become a strategic capability for space-faring nations.

From a business standpoint, the economics hinge on whether the value of defect-free wafers outweighs launch and recovery costs.

Early adopters may focus on niche, high-margin markets where performance gains justify the price — similar to how early carbon fibre was used only in aerospace before scaling into consumer products.

Sustainability Considerations

Making semiconductors in space could have environmental benefits.

Wafer fabrication on Earth requires large amounts of water, energy, and toxic chemicals.

By moving certain production steps into orbit, companies could potentially reduce the terrestrial environmental footprint of chip manufacturing — though life-cycle analysis is still needed to confirm net benefits.

Furthermore, platforms like ForgeStar-1 are reusable, minimising space debris and reducing the environmental impact of repeated launches.

Looking Ahead

The journey from ISS research experiment to full-scale orbital semiconductor fabrication is just beginning.

ForgeStar-1 will test whether zero-gravity manufacturing can move beyond small samples to market-ready wafer batches.

If successful, the term “zero-gravity semiconductors” could become as standard in electronics manufacturing as “EUV lithography” is today.

By cutting wafer defects by up to 80 percent, microgravity manufacturing doesn’t just promise better chips — it offers the potential to redefine the entire value chain of electronics.

The next revolution in computing power may not come from a new transistor design or fabrication technique, but from taking the fab itself into orbit.

£22.6 M Series A: What SpaceForge’s Record UK Funding Means for Space Industry Investment

(SpaceForge funding, UK space investment, Series A 2025, space industry finance)

In early 2025, UK-based space manufacturing pioneer SpaceForge closed a £22.6 million Series A funding round, the largest of its kind for a British space company to date.

This landmark raise signals more than just a big payday for the Cardiff-based startup — it’s a clear indication that UK space investment is entering a new, more ambitious phase.

The Deal That Made Headlines

The Series A 2025 round, backed by a mix of private investors, venture capital firms, and strategic partners, gives SpaceForge the capital needed to scale its in-orbit manufacturing capabilities.

Central to this expansion is ForgeStar-1, the company’s first returnable in-orbit foundry, due for launch later this year.

For context, most UK space startups raise seed or early pre-Series A rounds in the low millions.

Securing more than £20 million in one go is rare, particularly for a hardware-heavy venture.

This level of commitment suggests investors are confident that SpaceForge’s technology isn’t just scientifically interesting — it’s commercially viable.

Why Investors Are Betting Big

Several trends make SpaceForge’s business model especially appealing to investors:

Microgravity’s untapped potential — Experiments aboard the International Space Station have shown that microgravity can dramatically improve the quality of certain materials, from semiconductors to advanced alloys. SpaceForge’s returnable foundries aim to industrialise this advantage.

Reusable hardware — By designing satellites that can return to Earth, be refurbished, and relaunched, SpaceForge addresses cost efficiency and sustainability concerns — both hot topics in the investment world.

Growing demand for high-performance materials — Quantum computing, aerospace, defence, and telecommunications all require materials that could benefit from microgravity production.

First-mover advantage in Europe — While US companies such as Varda Space Industries are exploring similar concepts, SpaceForge is positioning itself as the European leader in orbital manufacturing.

The UK Space Sector Context

The UK government has set an ambitious goal: to capture 10 percent of the global space economy by 2030.

Achieving this requires more than satellite data services — it needs hardware innovation, in-orbit servicing, and manufacturing capabilities.

Until now, much of the UK’s space industry investment has focused on small satellite constellations, Earth observation, and launch facilities.

SpaceForge’s funding signals a shift toward value-added orbital services — a sector that could be worth billions globally in the coming decades.

ForgeStar-1 as the Test Case

The £22.6 million will help ensure that ForgeStar-1’s 2025 mission goes ahead with the best possible technical readiness. The satellite will carry out:

Microgravity metallurgy experiments, producing alloys with fewer defects and improved performance.

Semiconductor crystal growth trials, building on the defect-reduction potential demonstrated in ISS experiments.

Return capsule testing, proving the safety and integrity of payload recovery.

If ForgeStar-1 demonstrates both technical success and economic feasibility, the stage will be set for a fleet of returnable foundries.

Impact on Space Industry Finance

From an investment perspective, this Series A has a multiplier effect:

Validation of the sector — Other investors now see microgravity manufacturing as a serious commercial opportunity, not just a research project.

Catalyst for follow-on funding — If ForgeStar-1 meets its goals, Series B and later rounds could easily surpass this initial record.

Investor diversity — The participation of both traditional venture capital and strategic industrial partners suggests a healthy mix of short-term return expectations and long-term infrastructure building.

Risks and Challenges

Of course, this isn’t a guaranteed win. Hardware-first space companies face significant challenges:

Launch delays could push back commercial timelines.

High upfront costs mean profitability may take years.

Market education — convincing customers to switch to (or pay more for) materials made in orbit is an ongoing task.

However, the substantial Series A round gives SpaceForge a cushion to navigate these challenges without relying on constant short-term fundraising.

What This Means for the UK’s Space Ambitions

If successful, SpaceForge’s work could:

Cement the UK’s position as a global leader in orbital manufacturing.

Attract international customers seeking access to microgravity production without relying on US or Asian providers.

Stimulate regional economic growth in Wales and beyond through advanced manufacturing jobs and supply chain contracts.

More broadly, it could inspire greater investor appetite for other ambitious UK space ventures, from asteroid mining concepts to satellite servicing companies.

Looking Forward

The £22.6 M Series A is more than a milestone for one company — it’s a signal flare for the future of the UK’s space sector.

By backing SpaceForge, investors are betting that in-orbit manufacturing will be as transformative in the 21st century as container shipping was in the 20th.

If ForgeStar-1 delivers on its promise, the next few years could see Made in Space products becoming a mainstream reality — with Cardiff at the centre of this new industrial revolution.

Mycotecture:

Growing Mycelium-Based Habitats for Mars & Beyond

(mycelium habitats, mycotecture, fungal materials, space habitat construction)

When humans eventually settle on Mars or venture deeper into the Solar System, one of the biggest challenges will be building safe, durable, and sustainable habitats far from Earth’s supply chains.

Traditional construction materials like concrete or metal will be costly to launch, and transporting enough for entire bases could be economically impossible.

That’s why researchers are looking to an unexpected solution: mycotecture — the practice of growing structures from mycelium, the root-like network of fungi.

What is Mycotecture?

Mycotecture uses the natural growth properties of mycelium — the fibrous, branching network that forms the main body of a fungus — as a structural material.

When fed with plant-based waste, mycelium grows into a dense, sponge-like composite that can be moulded into almost any shape. Once dried, it becomes lightweight, strong, insulating, and biodegradable.

On Earth, mycelium is already used in packaging, furniture, and even experimental architecture. In space, its adaptability and low resource footprint could make it a game-changer for space habitat construction.

Why Mycelium for Space?

The advantages of mycelium habitats become clearer when we compare them to traditional space construction:

In-situ resource utilisation (ISRU) — Mycelium can be grown using local organic material, potentially including waste from crops grown on Mars or the Moon.

Lightweight transport — Instead of shipping bulky panels or beams, crews could bring lightweight spores and a growth substrate, then cultivate full-sized structures on site.

Self-repair potential — If kept alive in certain sections, mycelium structures could theoretically heal small cracks or damage.

Thermal insulation — Mycelium naturally resists heat transfer, helping regulate habitat temperatures.

Radiation shielding — Some fungi produce melanin, which can help absorb ionising radiation — a major hazard for astronauts beyond Earth’s magnetosphere.

NASA’s Myco-Architecture Studies

NASA’s Ames Research Center has been at the forefront of mycotecture for space research.

Its Myco-Architecture Project has demonstrated that mycelium can be grown into solid, load-bearing shapes that rival lightweight building materials.

The process is surprisingly simple:

Mould preparation — A shape or framework defines the final structure.

Mycelium inoculation — Spores are introduced to a nutrient-rich substrate.

Growth phase — The mycelium network expands, binding the substrate together.

Drying phase — Heat or desiccation stops fungal growth, solidifying the structure.

In a controlled Martian greenhouse, astronauts could theoretically grow an entire living module within weeks, using little more than stored spores, local materials, and recycled waste.

Mars: A Perfect Testbed

Mars presents unique challenges that mycotecture may be able to meet:

Radiation — Without a strong magnetic field, Mars receives high levels of cosmic rays. Mycelium reinforced with melanin could act as a biological radiation shield.

Temperature extremes — Mycelium’s insulation could help maintain stable interior conditions.

Dust storms — Mycelium composites can be designed to resist erosion from fine dust particles.

By combining mycelium with other local materials like Martian regolith, engineers could create fungal-regolith composites that provide both strength and shielding.

Beyond Mars: Lunar and Deep-Space Applications

The Moon offers similar opportunities, though its two-week day-night cycle and harsher temperature swings demand materials that can cope with thermal expansion and contraction.

Mycelium’s natural flexibility could give it an edge over brittle materials.

In deep space, fungal materials could even be integrated into spacecraft modules.

Inflatable habitats could be “seeded” with mycelium to grow internal radiation shielding layers during long voyages.

Sustainability Benefits

Traditional space habitats depend on materials that require high-energy processing, such as aluminium alloys and carbon composites.

Mycelium habitats could be grown on-demand with minimal processing energy, producing far fewer emissions if grown with renewable power.

They could also be composted or repurposed at the end of their lifespan.

Even on Earth, the lessons from mycotecture research could translate into greener building methods, reducing our dependence on cement — one of the world’s largest sources of CO₂ emissions.

Engineering Challenges

For all its promise, mycotecture faces technical hurdles:

Contamination control — Growth conditions must be kept sterile to prevent unwanted microbial growth.

Long-term durability — Mycelium can degrade in high-humidity environments unless fully sealed or treated.

Growth rate optimisation — Large-scale habitat growth will need faster cultivation methods than current prototypes.

Integration with life-support systems — Mycelium structures would need to interface with airlocks, plumbing, and electrical systems without compromising their integrity.

Addressing these challenges will be critical before mycelium habitats can move from lab experiment to space mission reality.

Looking Ahead

The vision is bold: imagine a Mars crew landing with nothing but spores, growth media, and mould frameworks — then “farming” their base into existence.

Mycotecture could transform space settlement from a purely industrial endeavour into something that feels almost organic.

With the mycelium habitat concept moving through NASA studies and commercial interest growing, we may one day see the first off-world buildings grown rather than assembled.

If successful, mycotecture could become a cornerstone of sustainable exploration — not just on Mars, but across the Solar System.

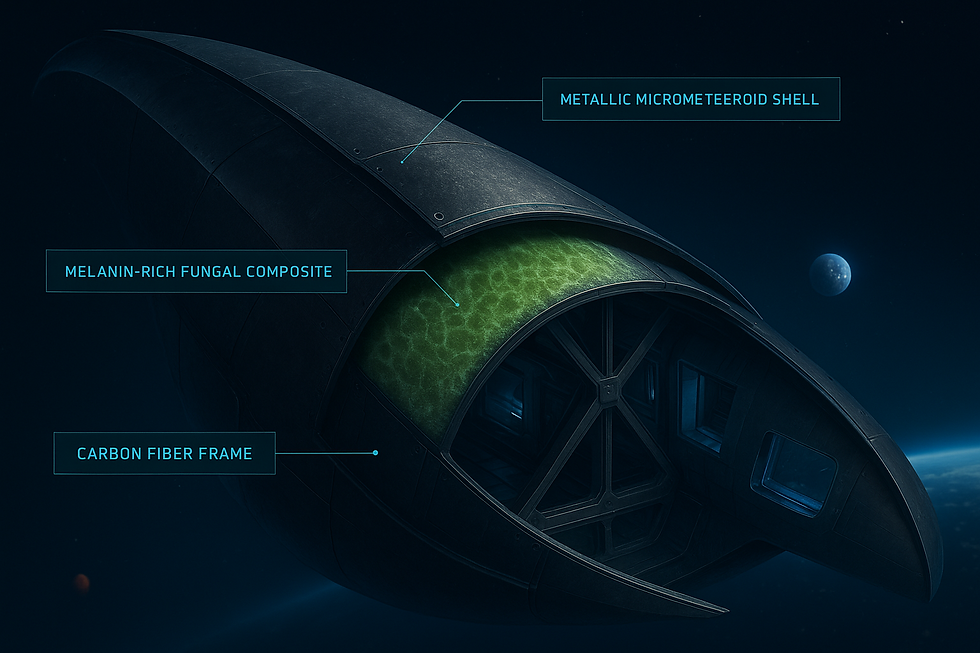

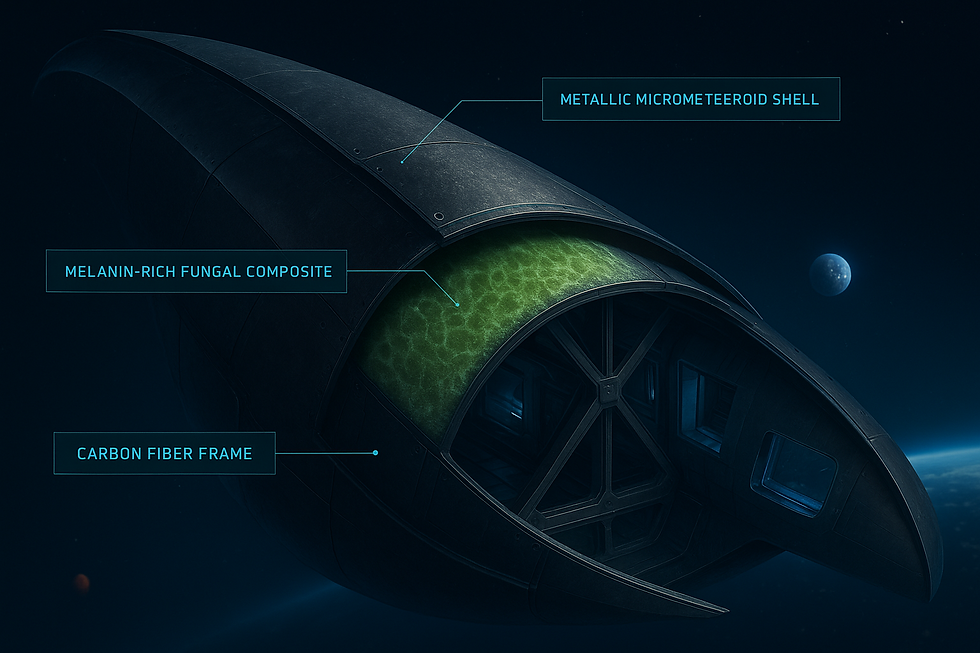

Biological Ship Hulls: Could Fungal Composites Shield Crews from Radiation?

(fungal composites, radiation shielding, biohull, spacecraft materials)

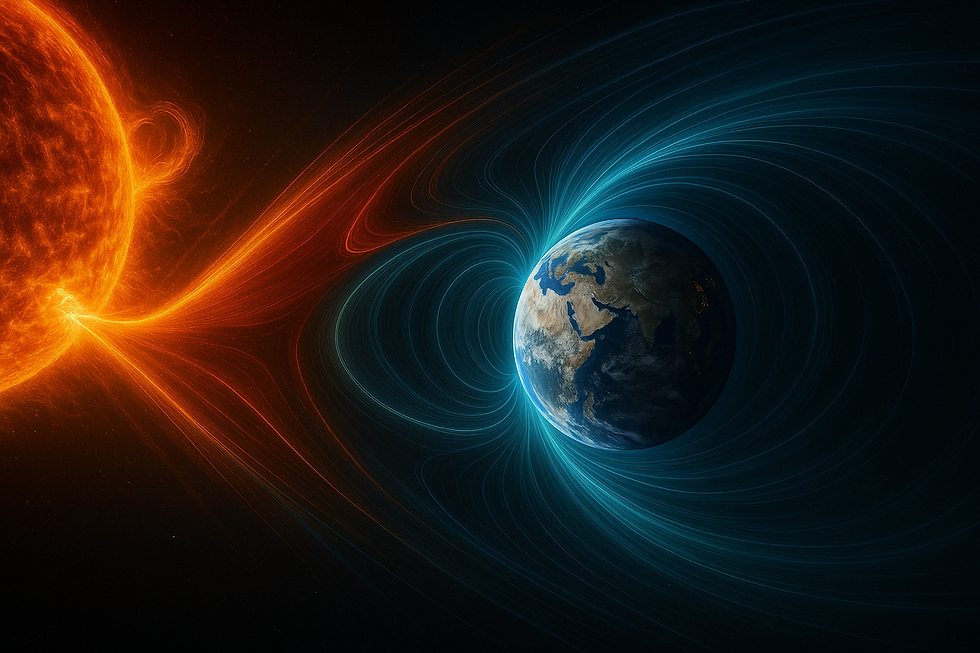

Space is not a friendly place for humans. Beyond Earth’s protective atmosphere and magnetic field, astronauts are exposed to cosmic rays and solar particle events that can damage DNA, increase cancer risk, and impair long-term health.

Current spacecraft rely on metal alloys and specialised polymers for protection, but these come with mass penalties and limitations.

An emerging line of research asks an unusual question: could fungal composites — materials grown from or incorporating fungi — provide lightweight, adaptable, and effective radiation shielding?

The Radiation Problem in Deep Space

On Earth, we’re shielded from the majority of ionising radiation by our atmosphere and magnetosphere.

In low Earth orbit (LEO), astronauts receive higher doses, but still benefit from partial protection.

Once we move beyond LEO — to the Moon, Mars, or deep space — radiation exposure increases dramatically.

Metallic shielding works by absorbing or scattering incoming particles, but to be effective against cosmic radiation, layers must be thick and heavy.

This drives up launch mass, making it costly to transport fully shielded habitats or spacecraft.

Fungal Composites: The Biohull Concept

A biohull is a hybrid spacecraft shell that incorporates biological components — in this case, fungal composites — into its structure.

The idea is to grow or integrate materials that naturally block radiation while offering other structural benefits.

One promising candidate is melanin-rich mycelium.

Melanin, a pigment found in certain fungi, can absorb and dissipate radiation energy.

Some species, such as Cladosporium sphaerospermum, have even been observed thriving in high-radiation environments, including the damaged Chernobyl nuclear reactor.

By growing mycelium within a composite matrix, engineers could produce panels that are lightweight, renewable, and radiation-resistant.

NASA and ISS Experiments

In 2019, researchers sent Cladosporium sphaerospermum to the International Space Station to study its growth and shielding potential. The results were promising:

The fungus grew normally in microgravity.

Radiation sensors detected a measurable reduction in ionising radiation beneath the fungal layer.

The material’s effectiveness increased as the mycelium matured, suggesting self-strengthening properties.

While these results were from thin biological layers, scaling the thickness could significantly improve shielding.

Advantages Over Traditional Materials

Lightweight transport — Instead of launching thick metal sheets, crews could bring spores and nutrient substrate, growing the shielding on-site.

Self-repair potential — Living mycelium can potentially heal microfractures or replace damaged material.

Multi-functionality — Fungal composites can provide structural support, insulation, and even life-support integration (e.g., oxygen production in symbiosis with algae).

Reduced waste — Growth-based production minimises manufacturing scrap.

How a Biohull Could Be Built

A biological ship hull might combine several layers:

Outer protective shell — Micrometeoroid and abrasion-resistant coating.

Fungal composite layer — Thick mycelium-rich section with melanin to absorb radiation.

Inner structural frame — Lightweight alloys or carbon composites for mechanical strength.

This modular approach means damaged sections could be replaced or regrown during long missions.

Challenges and Unknowns

While the concept is exciting, significant research is still needed:

Longevity — Spacecraft materials must withstand years of vacuum, radiation, and temperature extremes. Living materials may degrade unless carefully managed.

Containment — Keeping biological growth controlled to avoid contamination is essential.

Integration with other systems — A biohull must be compatible with spacecraft thermal control, air pressure systems, and docking interfaces.

Growth rate — Large areas of shielding would require rapid, reliable cultivation methods.

Addressing these issues will be critical before biohulls can move from concept to flight hardware.

Potential Applications

Mars transit vehicles — Ships making multi-month journeys between Earth and Mars could benefit from biohulls to protect crews from cumulative cosmic ray exposure.

Lunar surface bases — Growing fungal composite panels in-situ could reduce launch mass while providing both structural and radiation protection.

Deep-space exploration craft — Missions to asteroids or the outer planets could produce shielding on the way, reducing initial launch mass.

Sustainability Benefits

Fungal composites are inherently renewable.

Unlike mined metals, they can be regrown with minimal resource input.

If nutrient substrates are derived from space agriculture or recycled organic waste, biohulls could become part of a closed-loop life-support system.

On Earth, the same technology could inspire more sustainable, bio-based building materials, reducing reliance on high-energy industrial processes.

Looking Ahead

The idea of growing part of a spacecraft may sound like science fiction, but the first steps are already happening in orbit.

As fungal composites advance from lab tests to engineering prototypes, they could redefine how we think about spacecraft materials.

A biohull isn’t just a shield — it’s a living, adaptable part of a vessel, capable of growing alongside humanity’s ambitions in space.

With continued research, we might one day launch spacecraft not fully built, but seeded — ready to grow their own protection among the stars.

Closing Thoughts

From precision-engineered alloys forged in microgravity to habitats literally grown from living organisms, the Space Manufacturing & Bio-Materials revolution is blurring the lines between industry, biology, and exploration.

The innovations in these five articles show that the infrastructure of future space missions may not be launched fully formed from Earth — it could be built, grown, and adapted on-site, using both advanced engineering and the inherent capabilities of life itself.

As projects like ForgeStar-1 prove the economic and technical viability of orbital production, and as bio-material research unlocks new ways to build and shield our explorers, the foundation is being laid for a self-sustaining human presence in space.

These aren’t just experiments — they’re the first industrial steps toward a Solar System where manufacturing hubs orbit planets, colonies grow from spores, and spacecraft protect themselves with living armour.

In the decades ahead, the winners in the new space race may not be defined by how far they travel, but by how well they make use of the resources and environments they find along the way.

Space manufacturing isn’t just about building in space — it’s about building a future where space builds for us.

Comments