The Future of Spaceflight: Orbital Construction and Manufacturing

- Mr_Solid.Liquid.Gas

- Oct 29, 2025

- 3 min read

Updated: Dec 4, 2025

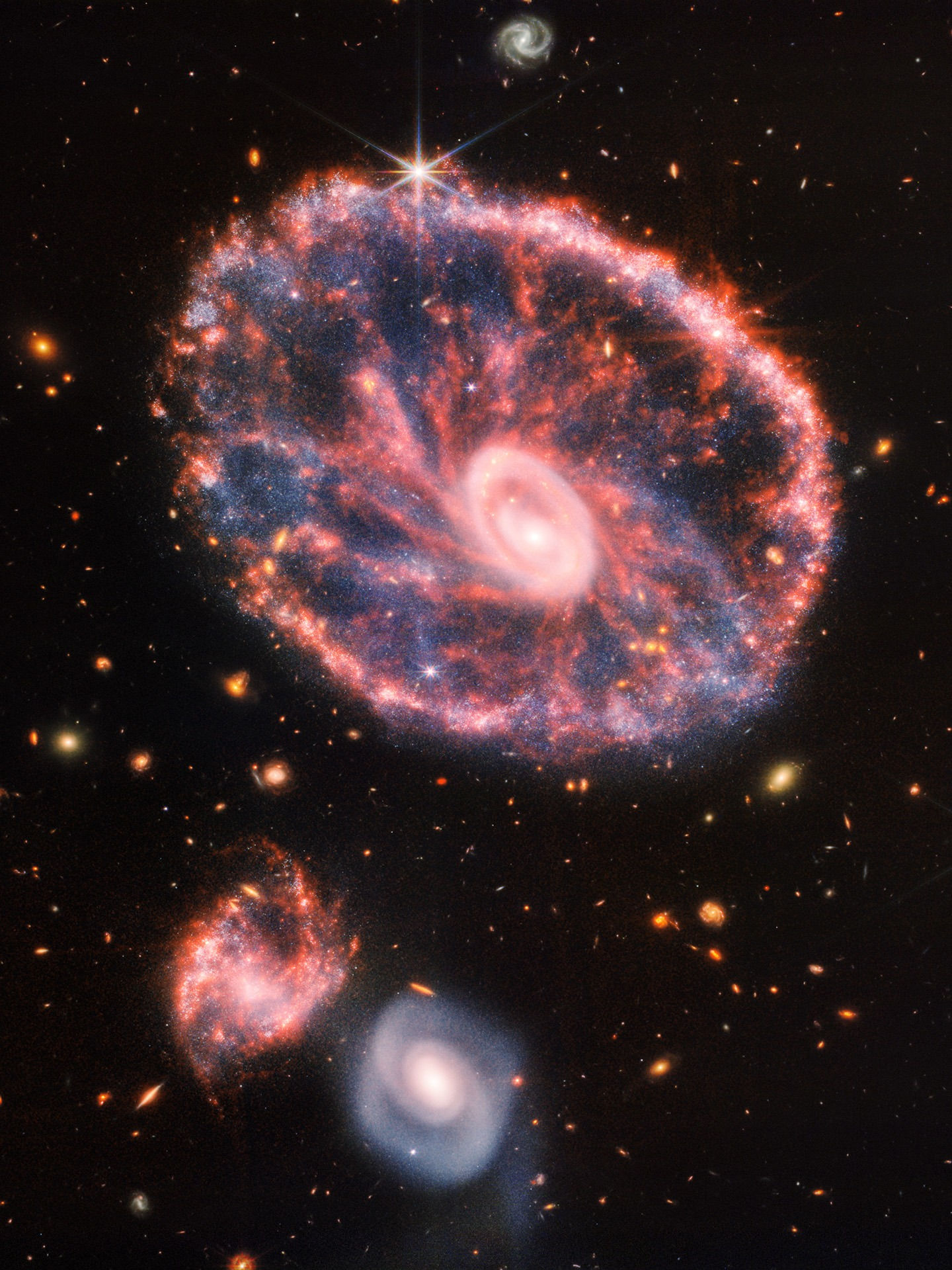

For a century, spaceflight meant launching finished hardware from Earth. That model is giving way to something more powerful: manufacturing, assembling, and repairing complex structures in orbit and beyond. Orbital construction blends robotics, autonomous control, materials science, and systems engineering to create assets too large, too delicate, or too modular to survive launch in one piece. It’s how we’ll build next‑gen telescopes, kilometer‑scale solar arrays, and habitats that make long‑duration living routine.

The Evolution of Space Manufacturing

The shift from Earth-based manufacturing to orbital construction represents a monumental change in how we approach space exploration. Traditional methods required launching complete systems, which limited design and functionality. Now, we can create components in space, drastically reducing the constraints imposed by launch capabilities.

This evolution opens up new possibilities for innovation. We can design larger structures and more complex systems that were previously deemed impossible. The future of space exploration is not just about reaching new frontiers; it's about building them.

3D Printing in Microgravity

Microgravity changes how materials melt, flow, cure, and crystallize. Additive manufacturing systems can exploit this to print high‑performance polymers, metals, and even glass without sagging under their own weight.

In‑orbit printers turn raw feedstock into brackets, ducts, truss nodes, and custom adapters, shrinking launch manifests and enabling on‑demand repairs. With in‑situ resource utilization, future printers could process asteroid‑sourced alloys, lunar regolith, or polymer precursors produced from carbon‑rich materials harvested in space.

Quality control is the hurdle. Without gravity, porosity, microvoids, and thermal gradients behave differently. Inline inspection—X‑ray CT, ultrasound, and machine‑vision metrology—closes the loop, while standardized test coupons validate each print batch. The goal is flight‑rated parts with traceable pedigree, produced meters from where they’ll fly.

Autonomous Assembly Systems

When structures grow beyond a single bay of a launch fairing, assembly must happen on‑orbit. Swarms of free‑flyer robots can rendezvous with pallets of components, perform precision alignment, and join panels using reversible fasteners or cold‑welding techniques.

Tethers and capture fixtures stabilize workpieces; cooperative manipulation allows multiple robots to handle flexible membranes without wrinkles or tears. Software is as important as hardware. Autonomy stacks combine SLAM (simultaneous localization and mapping), force‑torque feedback, and task planning to recover from off‑nominal conditions—thermal drift, actuator glitches, or micrometeoroid nicks—without waiting for ground intervention.

Lessons from the ISS, servicing missions, and commercial robotics transfer directly into robust orbital workflows.

Space Habitats and Rotating Stations

Habitats bring unique design pressures: radiation protection, micrometeoroid shielding, thermal control, and psychological well‑being. Inflatable modules provide excellent volume‑to‑mass ratios and can hide graded shielding layers.

For long stays, artificial gravity becomes a health enabler: rotating tori or dual‑hab counter‑rotating systems can deliver partial‑g to mitigate bone and muscle loss without constant centrifuge sessions. Interior architecture matters. Circadian‑lighting panels, acoustic zoning, and ‘view corridors’ reduce stress and disorientation.

Modular life‑support racks allow swap‑outs and upgrades over decades—crucial when the station is more city than spacecraft.

Lunar and Martian Manufacturing

The Moon and Mars are the natural next yards. Lunar regolith can be sintered into bricks, cast into basalt fiber, or smelted for oxygen and metals. On Mars, CO₂ and water ice feed chemical plants that produce plastics, methane, and oxidizer.

Local production slashes logistics costs and makes infrastructure resilient to supply interruptions from Earth. Surface construction needs dust‑tolerant mechanisms, wide‑temperature electronics, and sealed joints that shrug off abrasive regolith.

Hybrid crews—human specialists supervising fleets of semi‑autonomous machines—will set the tempo. Over time, these yards seed a cis‑lunar and interplanetary supply chain where raw resources move outward and finished systems move wherever missions demand.

Challenges and Solutions in Space Manufacturing

While the potential for orbital construction is immense, several challenges remain. Quality assurance, material limitations, and the need for reliable autonomous systems are just a few hurdles. However, advancements in technology and engineering are paving the way for solutions.

Investments in research and development will be crucial to overcoming these obstacles. Collaborations between space agencies, private companies, and academic institutions can drive innovation.

Conclusion

Orbital construction is not just a cost‑saver; it’s an enabler. Printing and assembling hardware where it will operate unlocks architectures impossible from Earth alone: sparse giant telescopes, modular power farms, and habitats sized for comfort, not just survival.

As quality assurance matures and autonomy proves itself, building in space becomes the default—not the exception. The future of spaceflight is bright, and the possibilities are limitless.

For more information on the advancements in space technology, visit Space Innovations.

Comments